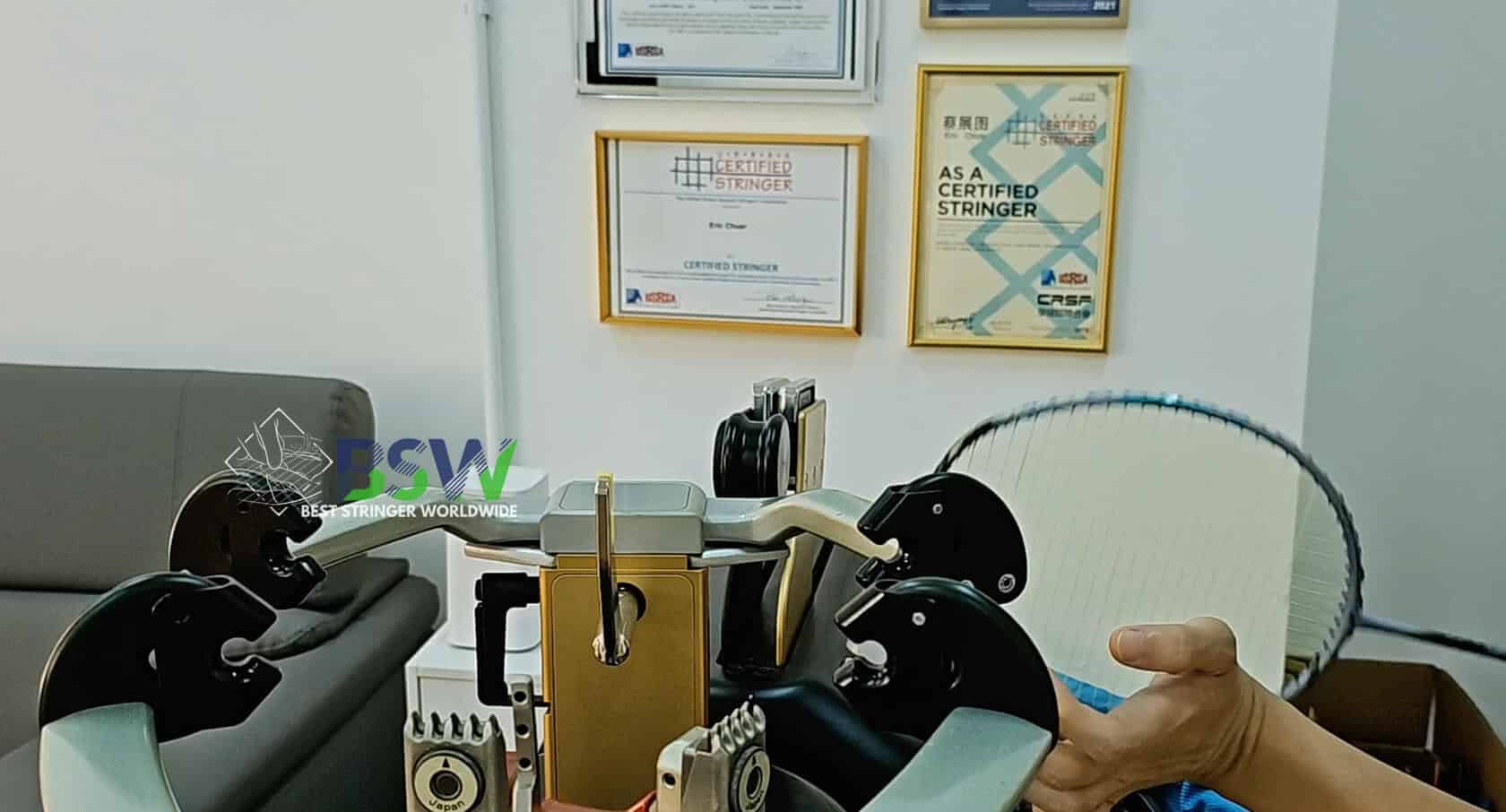

Tension systems are a crucial component of any stringing machine, ensuring that each string achieves the desired tension during the stringing process. For both professional stringers and players alike, understanding these systems is key to achieving optimal racquet performance. In this comprehensive guide, created by Best Stringer Worldwide (BSW) to help stringers and players improve their knowledge and skills, we’ll explore the intricacies of tension systems, their types, and how they impact the stringing process.

Introduction to Tension Systems

Tension systems are the heart of any stringing machine, playing a pivotal role in achieving consistent and accurate string tension. As technology has advanced, so too have these systems, offering stringers more precise control and a range of features to enhance the stringing process.

For those pursuing a racquet stringing certification or aiming to become a professional stringer, a deep understanding of tension systems is essential. This knowledge not only contributes to the quality of your work but also helps in selecting the right equipment for your needs.

Types of Tension Systems

There are two primary types of tension systems used in modern stringing machines: lock-out systems and constant-pull systems. Each has its own advantages and characteristics that can affect the final string tension and overall racquet performance.

Lock-out Systems

Lock-out systems, also known as “pull and hold” systems, operate by pulling the string to the set tension and then locking the string length in place. Here’s how they work:

- The tension head pulls the string to the desired tension.

- Once the set tension is reached, the system locks the string length.

- The stringer then clamps the string and releases the tension head.

Advantages:

- Simplicity in design and operation

- Often found in portable, manual stringing machines

- Generally more affordable

Disadvantages:

- May result in slightly lower final tension due to string elongation

- Requires adjustment in tension setting to compensate for tension loss

Constant-pull Systems

Constant-pull systems, as the name suggests, maintain tension on the string even after reaching the set value. This type of system is often found in electronic stringing machines. Here’s how they operate:

- The tension head pulls the string to the set tension.

- The system continues to apply tension, compensating for any immediate string elongation.

- This “compensation” typically lasts for a few seconds before the stringer clamps the string.

Advantages:

- Generally results in more consistent final tension

- Can provide more precise tension control

- Often equipped with additional features like pre-stretch options

Disadvantages:

- Usually more expensive

- May require power source, limiting portability

It’s worth noting that constant-pull systems typically result in 5-10% higher tension compared to lock-out systems for the same tension setting. Professional stringers often adjust their tension settings accordingly when switching between machine types.

Tension System Simulator

Tension Head Types

The tension head is the component of the stringing machine that physically pulls and holds the string. There are two main types of tension heads: linear pull and rotary.

Linear Pull Tension Heads

Linear pull tension heads move in a straight line away from the racquet to apply tension. This method closely mimics the traditional method of manual stringing.

Characteristics:

- Direct and intuitive operation

- Often equipped with a string gripper to reduce stress on the string

- May use various mechanisms (springs, electronics, or pneumatics) to generate tension

Rotary Tension Heads

Rotary tension heads use a rotating wheel or drum to pull the string and apply tension. This design can offer some unique advantages.

Characteristics:

- Can provide very smooth and consistent tension

- Often found in high-end electronic machines

- May allow for easier string handling in some situations

The choice between linear and rotary tension heads often comes down to personal preference and the specific needs of the stringer.

Additional Features of Tension Systems

Modern stringing machines, especially those aimed at professional stringers with stringing certificates, often come with additional features to enhance the stringing process and improve accuracy.

String Gripper Clamps

Many tension heads incorporate string gripper clamps with diamond-coated surfaces. These serve several purposes:

- Provide a secure grip on the string without excessive clamping force

- Reduce the risk of damaging the string during tensioning

- Allow for finer tension adjustments

However, it's crucial to maintain these clamps properly, as worn or dirty surfaces can lead to string slippage or damage.

Pre-stretch Function

Some electronic stringing machines offer a pre-stretch function, which can be particularly useful for certain string types. Here's how it works:

- The machine pulls the string to a tension higher than the set value.

- It holds this higher tension for a brief period (usually a few seconds).

- The tension is then reduced to the desired setting.

This process can help reduce overall tension loss, especially with strings that have higher elasticity.

Calibration and Accuracy

Regular calibration is crucial for maintaining the accuracy of your stringing machine's tension system. Most machines come with built-in calibration procedures, but it's also possible to use external tension calibrators for verification.

For professional stringers, maintaining and documenting regular calibration is often a requirement for keeping their stringing certification current.

Choosing the Right Tension System

Selecting the appropriate tension system depends on various factors:

- Volume of work: High-volume shops might benefit from the speed and consistency of electronic constant-pull systems.

- Portability needs: Traveling stringers might prefer manual lock-out systems for their portability.

- Budget: Electronic systems generally cost more but offer additional features.

- Types of strings used: Some systems handle certain string types (like polyester) better than others.

- Personal preference: Many professional stringers develop a preference based on their experience and stringing style.

Best Practices for Using Tension Systems

To get the most out of your tension system and maintain your professional stringer status, consider these best practices:

- Regular calibration: Check and calibrate your machine regularly, especially before important stringing jobs.

- Understand tension loss: Different strings and tensions will result in varying degrees of tension loss. Adjust your initial tension accordingly.

- Use appropriate clamps: Ensure your clamps are clean and in good condition to prevent slippage and maintain tension.

- Consider string type: Adjust your technique and possibly your tension settings based on the characteristics of the string you're using.

- Maintain your equipment: Keep your stringing machine clean and well-maintained for consistent performance.

The Impact of Tension Systems on String Performance

The tension system you use can have a significant impact on the final performance of the racquet. Here's how:

- Consistency: More accurate tension systems lead to more consistent string beds, which can improve player confidence and performance.

- Playability: Different tension systems may affect the initial playability of the strings, with some players preferring the slightly lower tension often resulting from lock-out systems.

- Durability: Accurate and consistent tensioning can contribute to improved string durability by ensuring even load distribution across the string bed.

- Feel: Some players report being able to feel the difference between racquets strung on different types of machines, though this can be highly subjective.

Future Trends in Tension System Technology

As technology continues to advance, we're seeing exciting developments in tension system technology:

- Improved accuracy: New sensors and control systems are pushing the boundaries of tension accuracy.

- Smart features: Some machines now offer programmable stringing patterns and tension profiles.

- Data logging: Advanced systems can log stringing data, helping stringers track their work and maintain consistency.

- Integration with materials science: As new string materials are developed, tension systems are evolving to handle their unique properties more effectively.

For professional stringers, staying informed about these trends is crucial for maintaining their competitive edge and ensuring they can offer the best possible service to their clients.

Tension Systems Quiz

1. What are the two primary types of tension systems used in modern stringing machines?

2. Which system typically results in 5-10% higher tension compared to the other for the same tension setting?

3. What is a key advantage of lock-out systems?

4. What is the purpose of the pre-stretch function in some electronic stringing machines?

5. What type of tension head moves in a straight line away from the racquet to apply tension?

Understanding tension systems is a crucial aspect of becoming a proficient and professional stringer. Whether you're pursuing a racquet stringing certification or looking to improve your skills, this knowledge forms the foundation of delivering consistent, high-quality string jobs.

Remember, while the technology behind tension systems continues to evolve, the fundamental principles remain the same. By mastering these principles and staying informed about new developments, you'll be well-equipped to provide top-notch stringing services and maintain your status as a professional stringer.

Best Stringer Worldwide (BSW) is committed to providing educational resources like this to help stringers and players improve their knowledge and skills. We encourage you to continue exploring and learning about the fascinating world of racquet stringing!

About Best Stringer Worldwide

Best Stringer Worldwide is a comprehensive badminton and tennis stringing education program. We provide in-depth training on stringing techniques, racquet technology, and player-specific customization. Our curriculum is designed to help stringers understand and meet the needs of all badminton players, from casual enthusiasts to competitive athletes.

Read More