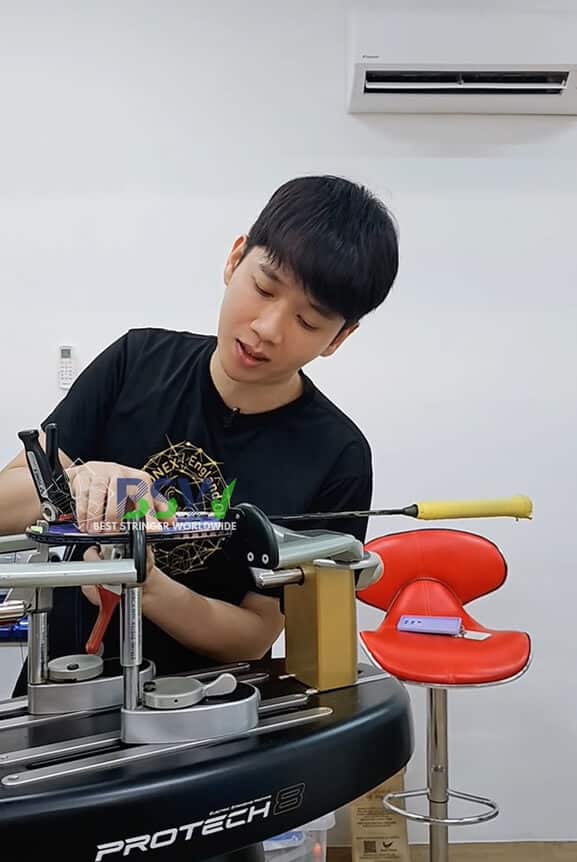

Racquet stringing is a precise art that requires not only skill but also the right tools. Among these tools, the clamp system stands out as one of the most crucial components of a stringing machine. This comprehensive guide, created by Best Stringer Worldwide (BSW) to help stringers and players improve their knowledge and skills, delves into the intricacies of clamp systems and their impact on the stringing process.

Introduction to Clamp Systems

The clamp system is a vital part of any stringing machine. Its primary function is to hold the strings firmly in place after the tension head has pulled them to the desired tension. This ensures that the strings maintain their tension throughout the stringing process.

The importance of a reliable clamp system cannot be overstated. Even the slightest slippage in the clamps can compromise the entire stringing job. If a string moves within the clamp, it can lead to damage to the string surface, potentially resulting in premature breakage and loss of customer trust.

Clamp System Simulator

Types of Clamp Systems

There are three main types of clamp systems used in stringing machines:

- Flying Clamps

- Rotational Fixed Clamps

- Non-rotational Fixed Clamps

Let’s explore each of these in detail.

Flying Clamps

Flying clamps are often associated with non-professional stringing machines. As the name suggests, these clamps are not attached to the stringing machine itself.

How they work:

- Flying clamps grip two adjacent strings at once.

- The tension head then pulls the next string to the desired tension.

- The process is repeated along the string bed.

Pros of Flying Clamps:

- Lightweight and portable

- Suitable for beginners who are less sensitive to string bed stiffness

- Often used in machines designed for badminton racquets, where tension requirements are typically lower

- More affordable than machines with fixed clamps

Cons of Flying Clamps:

- Generally made of plastic or softer metals, making them less durable

- May not maintain consistent tension as effectively as other clamp types

- Can be more challenging to use efficiently, potentially slowing down the stringing process

Rotational Fixed Clamps

Rotational fixed clamps are connected to the stringing machine and can rotate in any direction. This design allows them to securely hold strings on racquets with fan-shaped string patterns.

Key Features:

- Use a sliding post design, eliminating the need to change tracks when switching from main to cross strings

- Typically made of steel for increased durability

- Most popular type of clamp in modern stringing machines

How they work:

Most rotational fixed clamps have two locking mechanisms:

- One to secure the string within the clamp

- Another to fix the clamp’s position on the machine

Proper use of both locking mechanisms is crucial to prevent tension loss and string damage.

Pros of Rotational Fixed Clamps:

- Versatile and able to accommodate various racquet shapes

- Durable construction

- Provide consistent and reliable string holding

Cons of Rotational Fixed Clamps:

- More complex to use than flying clamps, requiring proper training

- Can potentially damage strings if not used correctly

Many professional-grade stringing machines feature two rotational fixed clamps for efficient stringing. Some advanced models even offer a single 360-degree rotational clamp, which can move freely around the racquet. However, these single-clamp systems often require the use of a flying clamp or starting clamp to assist in the stringing process.

Non-rotational Fixed Clamps

Also known as glide bar clamps, these are attached to a sliding bar on the stringing machine. They can only rotate to two positions: 0 degrees and 90 degrees.

Key Features:

- Do not require the clamp base to be fixed when clamping strings

- Require the sliding bar to be removed and repositioned when switching from main to cross strings

Pros of Non-rotational Fixed Clamps:

- Simple to use

- Provide consistent clamping pressure

Cons of Non-rotational Fixed Clamps:

- Less versatile than rotational clamps

- Slower to use when switching between main and cross strings

- Less common in modern stringing machines

Clamp System Quiz

Advanced Clamp Features

As stringing technology has evolved, manufacturers have introduced advanced features to improve clamp performance and protect string integrity.

Diamond Dust Treatment

Many modern clamps feature a rough, sandpaper-like surface on the inside of the clamp jaws. This treatment, often referred to as "diamond dust," is designed to increase friction between the clamp and the string.

Benefits of Diamond Dust Treatment:

- Allows for secure string holding with less clamping pressure

- Reduces the risk of crushing or deforming strings

- Improves overall stringing consistency

Potential Drawbacks:

- If clamp tension is set too loose, strings may still slip

- The rough surface can potentially cause more noticeable damage if slippage occurs

Adjustable Clamp Tension

Some advanced stringing machines offer clamps with adjustable tension settings. This feature allows stringers to fine-tune the clamping pressure based on the string type and gauge.

Advantages of Adjustable Clamp Tension:

- Accommodates different string thicknesses without over or under-clamping

- Reduces the risk of string damage from excessive clamping force

- Allows for consistent clamping pressure across different string jobs

How to Use:

- Adjust clamp tension according to the string's thickness and material

- Some clamps can be adjusted without tools, while others may require a specific adjustment tool

String Materials Comparison

| Material | Durability | Power | Control | Comfort |

|---|---|---|---|---|

| Natural Gut | Low | High | Medium | High |

| Multifilament | Medium | High | Medium | High |

| Polyester | High | Low | High | Low |

Choosing the Right Clamp System

For those pursuing racquet stringing certification or aiming to become a professional stringer, understanding the nuances of different clamp systems is crucial. The choice of clamp system can significantly impact stringing efficiency, consistency, and overall quality.

Factors to Consider:

- Skill Level: Beginners might find flying clamps easier to use initially, while experienced stringers often prefer the precision of fixed clamps.

- Type of Racquets: If you primarily string badminton racquets, a machine with flying clamps might suffice. For tennis and squash racquets, fixed clamps are generally preferred.

- Stringing Volume: High-volume shops benefit from the efficiency of dual rotational fixed clamps.

- Portability Needs: If you need to transport your machine frequently, a system with flying clamps might be more convenient.

- Budget: Fixed clamp systems are typically more expensive but offer greater precision and durability.

- String Types: If you work with a wide variety of string materials and gauges, a system with adjustable clamp tension is beneficial.

Maintenance and Care of Clamp Systems

Proper maintenance of your clamp system is essential for consistent performance and longevity. Here are some tips for keeping your clamps in top condition:

- Regular Cleaning: Clean the clamp jaws regularly to remove any string residue or debris.

- Lubrication: For rotational clamps, apply a small amount of lubricant to the moving parts as recommended by the manufacturer.

- Inspection: Regularly check for any signs of wear or damage, particularly on the clamping surfaces.

- Proper Storage: When not in use, store your stringing machine in a clean, dry environment to prevent corrosion.

- Calibration: Periodically check and adjust the alignment and tension of your clamps according to the manufacturer's instructions.

Clamp Maintenance Checklist

The clamp system is a critical component of any stringing machine, playing a vital role in producing consistently strung racquets. Whether you're a beginner working towards your stringing certificate or a professional stringer with years of experience, understanding the nuances of different clamp systems can help you improve your stringing quality and efficiency.

As you continue to develop your skills, consider the impact that different clamp systems can have on your work. Remember that while having a high-quality stringing machine with an advanced clamp system is important, it's the skill and knowledge of the stringer that truly makes the difference.

Best Stringer Worldwide (BSW) is committed to advancing the art and science of racquet stringing. By providing educational resources like this guide, we aim to support the development of skilled stringers and enhance the overall quality of racquet preparation in the industry. Whether you're pursuing racquet stringing certification or simply striving to improve your skills, understanding the tools of the trade is an essential step on your journey to becoming a professional stringer.

About Best Stringer Worldwide

Best Stringer Worldwide is a comprehensive badminton and tennis stringing education program. We provide in-depth training on stringing techniques, racquet technology, and player-specific customization. Our curriculum is designed to help stringers understand and meet the needs of all badminton players, from casual enthusiasts to competitive athletes.

Read More