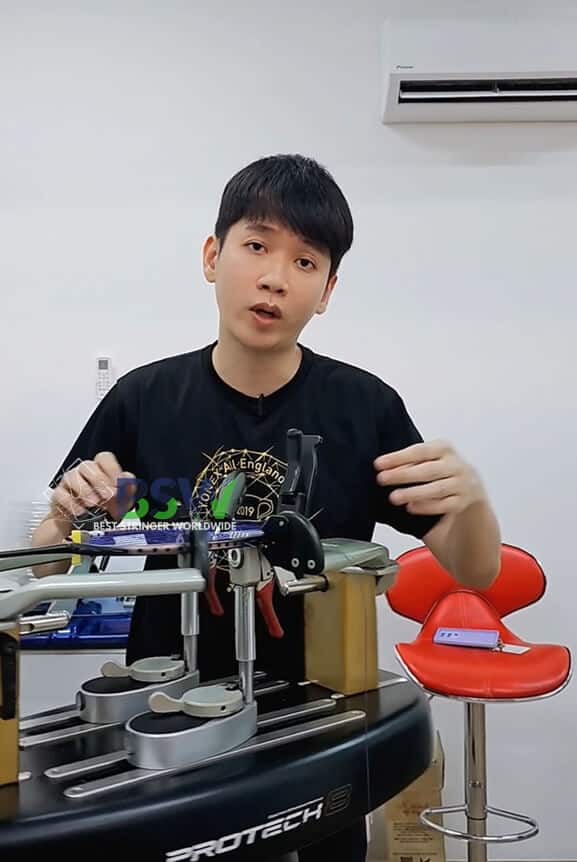

Stringing machines are essential tools for professional stringers and racquet sports enthusiasts alike. Understanding their structure and components is crucial for anyone seeking to master the art of racquet stringing. This comprehensive guide, created by Best Stringer Worldwide (BSW) to help stringers and players improve their knowledge and skills, delves into the intricate anatomy of stringing machines.

Introduction to Stringing Machine Components

A stringing machine consists of three primary systems that directly impact its performance:

- Mounting System

- Clamp System

- Tension System

Each of these systems plays a vital role in the stringing process and contributes to the overall quality of the strung racquet. Let’s explore each system in detail.

Stringing Machine Anatomy

The Mounting System

The mounting system is responsible for securely holding the racquet in place during the stringing process. A high-quality mounting system should:

- Distribute pressure evenly across the racquet frame to prevent damage

- Provide adequate support to maintain the racquet’s shape

- Offer versatility to accommodate different racquet types (tennis, badminton, squash)

Types of Mounting Systems

- 6-Point Mounting System (External Mount)

- Most common in modern stringing machines

- Uses six fixed points at 2, 4, 6, 8, 10, and 12 o’clock positions

- Four adjustable clamps at 2, 4, 8, and 10 o’clock secure the frame

- L-shaped supports at 6 and 12 o’clock provide additional stability

- 2-Point Mounting System (Drop-Weight Mount)

- Faster mounting process with fewer adjustments

- Main support points at 6 and 12 o’clock positions

- Larger contact area with the frame (often covering 10-2 o’clock at the head and 4-8 o’clock at the throat)

- Hybrid Mounting System

- Combines features of 6-point and 2-point systems

- Drop-weight style mounts at 6 and 12 o’clock

- External mounts at 2, 4, 8, and 10 o’clock

- Provides maximum frame contact and support

Key Features of Mounting Systems

- Synchronized Adjustment: Modern machines often allow simultaneous adjustment of multiple mounting points (e.g., 2 and 10 o’clock, 4 and 8 o’clock)

- Adaptability: High-quality systems require fewer adapters for different racquet shapes

- Visibility: External mounting systems offer better visibility of string holes during the stringing process

For those pursuing racquet stringing certification or aiming to become a professional stringer, understanding the nuances of different mounting systems is crucial. It affects not only the efficiency of the stringing process but also the protection of the racquet frame.

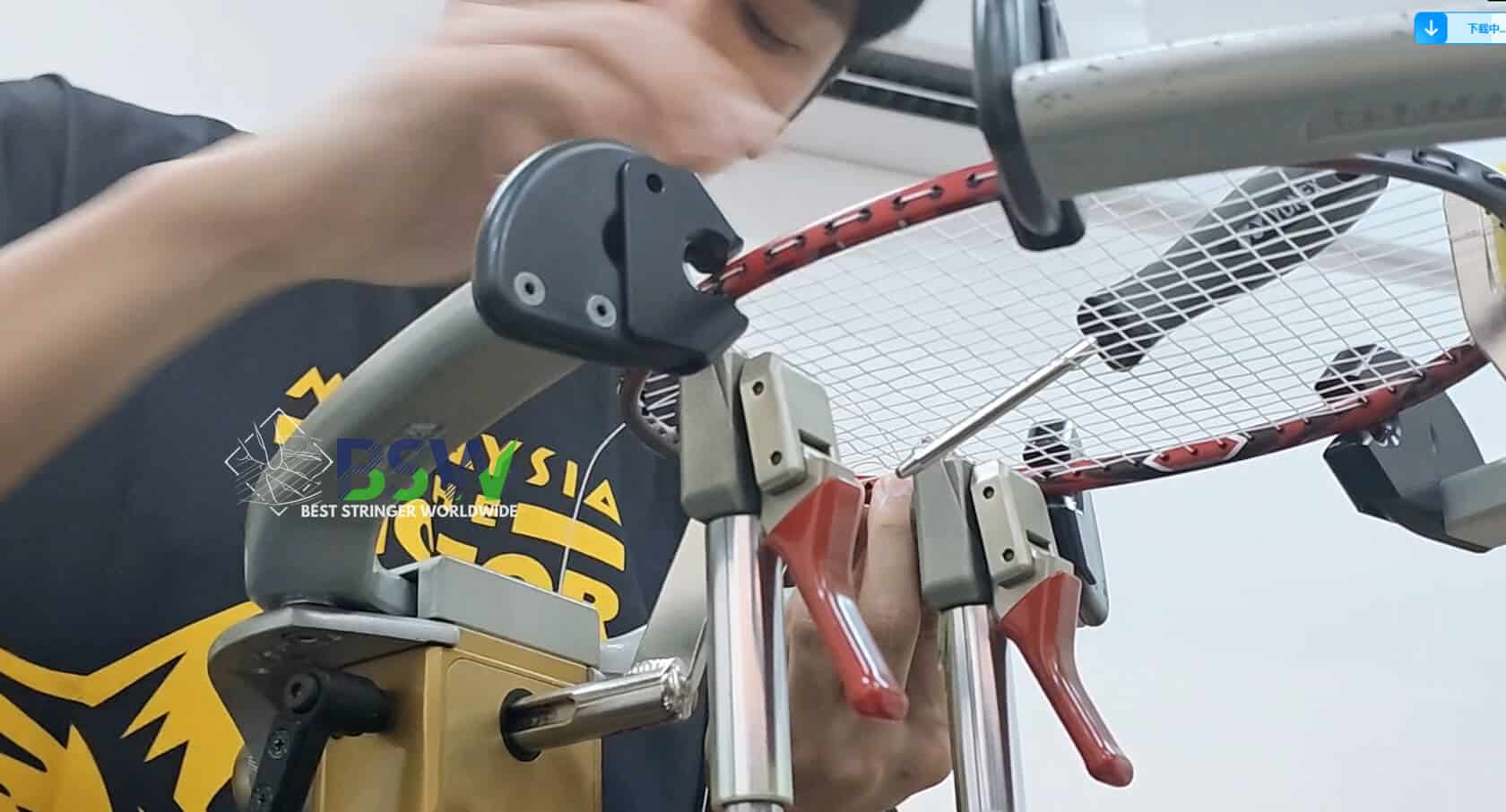

The Clamp System

The clamp system is responsible for holding the strings in place during the stringing process. Effective clamps should:

- Securely grip the string without causing damage

- Allow for quick and easy repositioning

- Maintain consistent pressure throughout the stringing process

Types of Clamp Systems

- Fixed Clamps

- Attached to specific points on the machine

- Require manual repositioning during stringing

- Often found on entry-level or older machines

- Flying Clamps

- Portable clamps that can be placed anywhere on the string

- Offer more flexibility in the stringing process

- Popular among experienced stringers for their versatility

- Glide Clamps

- Combine features of fixed and flying clamps

- Attached to rails that allow smooth movement around the racquet

- Provide stability of fixed clamps with some flexibility of flying clamps

Key Considerations for Clamp Systems

- Grip Strength: Clamps must hold strings firmly without slipping or damaging them

- Ease of Use: Quick release mechanisms and ergonomic designs improve efficiency

- Durability: High-quality materials ensure longevity and consistent performance

Professional stringers often develop preferences for specific clamp systems based on their stringing techniques and the types of racquets they frequently work with. As part of stringing certificate programs, stringers learn to use various clamp systems effectively.

The Tension System

The tension system is the heart of any stringing machine, responsible for applying and maintaining the desired string tension. A reliable tension system ensures consistency and accuracy in the stringing process.

Types of Tension Systems

- Drop Weight Systems

- Use gravity and leverage to apply tension

- Simple, durable, and generally accurate

- Require manual operation and can be time-consuming

- Spring Tension Systems

- Utilize compressed springs to generate tension

- Faster than drop weight systems

- May require periodic calibration to maintain accuracy

- Electronic Tension Systems

- Use electric motors to apply tension

- Offer precise control and consistency

- Often include programmable settings for different string patterns

Lock-out vs. Constant-pull Systems

Tension systems can be further categorized based on their ability to maintain tension:

- Lock-out Systems: Cannot maintain tension or provide “compensation” after initial pull

- Constant-pull Systems: Can maintain tension and offer “compensation” features

Drop weight systems and modern electronic machines are typically constant-pull, while some older electric and manual crank machines are lock-out systems.

Tension System Comparison Quiz

Additional Features of Stringing Machines

Turntable Lock

The turntable lock is a feature that prevents the rotation of the machine's turntable. It serves two primary purposes:

- Stabilizes the racquet during tension calibration and knot tying

- Prevents unwanted rotation when stringing racquets with large string holes (e.g., Prince O3 technology)

360-Degree Rotation

Many modern stringing machines offer 360-degree rotation of the mounting system. This feature:

- Improves access to all parts of the racquet during stringing

- Reduces the need to reposition the racquet manually

- May introduce slight tension variations due to the angle between the string and frame

Some manufacturers have addressed potential tension issues by designing tension heads that automatically elevate, ensuring the string and frame remain on the same plane during tensioning.

Stringing Process Simulator

Choosing the Right Stringing Machine

When selecting a stringing machine, consider the following factors:

- Volume of Work: High-volume shops may benefit from electronic machines for speed and consistency

- Types of Racquets: Ensure the machine can accommodate all racquet types you plan to string

- Portability: Consider a tabletop model if you need to transport the machine frequently

- Budget: Balance features with cost, keeping in mind long-term value and potential for increased efficiency

Remember that while the technology in stringing machines may not be as advanced as in other consumer electronics, their specialized nature and lower production volumes contribute to their higher costs.

The Importance of Professional Stringing

Understanding the anatomy of stringing machines is just one aspect of becoming a proficient stringer. Professional stringers must also:

- Develop a deep understanding of string properties and racquet design

- Stay updated on the latest stringing techniques and technologies

- Cultivate attention to detail and consistency in their work

Many organizations offer racquet stringing certification programs, which can help stringers validate their skills and knowledge. A stringing certificate can be a valuable credential for those looking to establish themselves in the industry.

Certification Tester Racquet Stringing Feedback

The structure of stringing machines may seem complex at first, but understanding their components and functions is essential for anyone serious about racquet stringing. Whether you're a professional stringer, an aspiring technician, or an enthusiastic player, this knowledge will help you appreciate the intricacies of the stringing process and make informed decisions about equipment and techniques.

Best Stringer Worldwide (BSW) is committed to advancing the art and science of racquet stringing. By providing educational resources like this guide, we aim to support the development of skilled stringers and enhance the overall quality of racquet preparation in the industry.

Remember, while having a high-quality stringing machine is important, it's the skill and knowledge of the stringer that truly makes the difference. Continuous learning, practice, and attention to detail are the hallmarks of a great stringer. Whether you're pursuing racquet stringing certification or simply striving to improve your skills, understanding the tools of the trade is an essential step on your journey to becoming a professional stringer.

About Best Stringer Worldwide

Best Stringer Worldwide is a comprehensive badminton and tennis stringing education program. We provide in-depth training on stringing techniques, racquet technology, and player-specific customization. Our curriculum is designed to help stringers understand and meet the needs of all badminton players, from casual enthusiasts to competitive athletes.

Read More